Home » Posts tagged 'stamped concrete'

Tag Archives: stamped concrete

The Importance of Concrete Repair

Concrete damage can be costly to repair. Left untreated, minor cracks and surface discoloration can worsen, eventually compromising the structural integrity of concrete structures.

Choosing the right repair method for any given problem is important to ensure long-term success. Many factors must be considered, including the type of damage, location and intended use of the concrete. Contact Concrete Repair Dallas now!

Concrete is the backbone of modern infrastructure, and is used in a wide range of situations, from floors in warehouses and factories, to car parks, garage forecourts and children’s playgrounds. It’s a durable material, but even the toughest concrete surfaces aren’t immune to damage and wear over time. When the time comes to repair these surfaces, contractors must understand the importance of proper surface preparation and how to do it correctly to ensure the longevity of the repairs.

The first step in the concrete repair process is a thorough assessment of the damaged area by experienced professionals. This will determine the appropriate concrete repair methods and products to use. Concrete repairs are only as good as the surface they are applied to, so the next important step is cleaning the concrete to remove contaminates and create a clean surface for the repair materials to bond to. This can be done using physical methods such as sand blasting, grinding or pressure washing. Chemical treatments such as acid etching can also be used to remove contamination from the concrete surface.

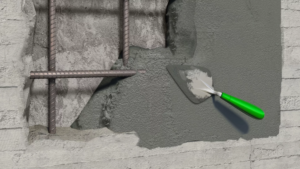

Once the concrete surface is cleaned, it must be profiled to create a roughened surface that will facilitate the mechanical bond of the concrete patching product. This can be achieved with hand tools such as a wire brush, power brushes or scrapers. It may also be possible to lightly profile the surface with a mechanical grinder. A dust control system should be in place during this stage of the process to minimise the generation of dust and debris.

It is important to pre-dampen the outlined repair area before filling to prevent water loss from the concrete patching product. This will also help prevent the concrete from cracking as it cures. Ideally, the concrete should be dampened until it is saturated but not soaking wet.

It is also important to apply a ‘scratch’ coat before placing the main body of the concrete. This is a wet coat that is made up of the same mix as the repair product and consists of a small amount of water mixed with the product to a soupy consistency. The slurry is then brushed onto the repaired surface with a gloved hand. This allows the cement particles to hydrate before they harden and creates an effective mechanical bond.

Materials

The selection of repair materials and their proper application is the key factor in a successful concrete repair. For this reason, care must be taken to choose the right material for the job, considering factors such as dimensional characteristics (especially drying shrinkage), thermal properties, and whether the repaired area will be subjected to load. Also important are the chemical resistance and durability requirements of the repair material.

Portland cement mortar or grout is the most commonly used repair material. It has high mechanical strength and rapid hardening, but it also has relatively high drying shrinkage and lower flexural and abrasion strengths than concrete. In addition, if the repair area is exposed to freezing and thawing conditions, the repair material should be durable against these conditions.

There are many other types of repair materials that may be more suitable for specific situations. For example, epoxy injections are often used to fill thin cracks, as they expand and contract with the surrounding concrete, resulting in a strong bond. Hydraulic cement is another good option for small cracks, as it will seal the cracks and set quickly. For more serious repairs, a concrete patching mix can be mixed with fly ash or blast furnace slag to provide higher strength and durability.

Many researchers have studied the interface between repair materials and concrete substrates. The interfacial adhesion between them is of major concern. The bond between the repair material and the old concrete is mainly governed by the interfacial surface area and the microstructure of the interface.

The permeability and the water content of the substrate also influence the bond between the repair material and the substrate. The bond strength is higher when the substrate is pre-saturated. On the other hand, excess moisture can reduce the interfacial adhesion between the repair material and the substrate.

The interfacial adhesion between alkali-activated concrete (AAM) and the existing concrete can be enhanced through the application of silane-based interfacial coupling agent. Gomaa et al. [83] characterized the microstructure of the interface between AAM and concrete using mercury intrusion porosimeter tests and scanning electron microscope (SEM) analysis. They found that AAM had a denser microstructure with more calcium aluminate silicate hydrate compared to ordinary concrete.

Routing and Sealing

The routing and sealing stage of concrete repair involves the application of a special filler or epoxy to concrete cracks. This step may also involve removing deteriorated concrete from the damaged areas and draining water to reduce moisture and structural stress that cause damage.

It’s important to identify all the factors causing cracking so that they can be addressed in the repair process. You can use destructive and nondestructive evaluation techniques to do this. Destructive methods such as a percussion or chipping hammer can remove the damaged concrete without major damage to the surrounding sound concrete. Nondestructive evaluations such as radar and infrared thermography can also reveal a lot of information without having to open up the concrete.

When routing and sealing concrete, you must choose a material that is compatible with the existing surface and that will provide a good bond with the concrete. Typical materials include epoxies, silicones and urethanes. Different sealants have different tolerances for crack movement and expansion.

Before applying the concrete crack filler or epoxy, apply a thin layer of bonding agent to the surface. This will help the new material adhere to the existing concrete and improve the strength of the repaired area. This step is often overlooked but it’s important for a successful repair.

After the concrete has cured, you can apply a commercial concrete sealer. This will prevent future damage from water intrusion, weeds and other environmental contaminants. It will also increase the life of the repaired concrete and make the surface easier to clean and maintain.

The concrete repair and restoration process can be time consuming and labor intensive. It’s important to take all the necessary safety precautions and to seek professional help when needed. A reliable contractor can save you time and money in the long run by repairing your concrete structures quickly and correctly.

In addition to repairing concrete damage, a professional can help you create a beautiful decorative finish for concrete floors and walls. They will use advanced tools and techniques that can improve the aesthetic appeal of your home or business and make it stand out from the competition.

Lifting

For concrete repair, it’s important to choose the right products and application techniques. This ensures that the repair is safe and effective, and will last longer. It’s also important to take preventative steps to keep concrete from becoming damaged, such as regular cleaning and sealing. Sealing helps protect concrete surfaces from water absorption and harsh weather conditions, which can cause cracks or other damage. It’s also important to address problems promptly, as small cracks or other issues can quickly escalate into major issues.

One of the most common repair methods is to raise sunken slabs. This process is known as “concrete lifting,” and it involves drilling holes in the sunken area and pumping stabilizing grout underneath the slab. This process can be more efficient than tearing out and replacing the slab, as it saves time and money.

Concrete lifting is often used to repair sunken patios, driveways, sidewalks and swimming pool decks. It can also be used to raise the level of a house’s foundation or a basement floor. This method of repair is particularly helpful for areas that are frequently used, as it can prevent uneven wear and tear and prevent the formation of large cracks.

When repairing existing concrete, it’s necessary to use a bond coat that is made from equal parts sand and cement. The bond coat should have the consistency of whipped cream and be applied to the entire surface of the existing concrete. This will help to create a strong, durable connection between the new and old concrete, which is critical for long-term durability.

Another consideration is the type of concrete used for the repair. It should be strong enough to carry the design loads, durable enough to resist the forces of weathering, and economical in terms of initial cost and lifetime service costs. In addition, it should be suitable for the construction process and have good permeability and freeze-thaw durability properties.

Once the concrete has cured for a month, it’s important to apply a concrete sealer that will help to protect and prolong the life of the concrete. A quality concrete sealer will prevent moisture from seeping into the pores of the concrete and causing damage, and it can protect the concrete against chemicals and other harmful substances that may come into contact with it.